The Astromech.net club has a lot of really useful files, including some very carefully drawn blueprints. Read it all carefully 10 times.

I've built the Mike Senna/Matthew Henrick wooden frame laid out there. They're good plans. There are few gaps, a few typos, and few outright mistakes, but they're free and overall very good. Mike Senna and Matthew Henrick have been really helpful to me on email with questions and clarifications too.

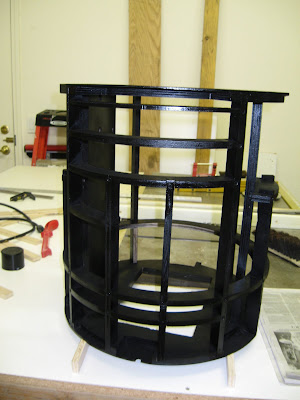

Here's the end result, all painted black and sexy.

A couple of issues: After comparing the skin blueprints and the frame, I figured out that the frame comes out to be 19.09 inches and the skins are 19.35 inches. So that's a 1/4" overlap. I couldn't figure out what to do with that extra skin. After emailing Henrick and Senna, I think we concluded that the plans show the uprights to be too short. I ended up recutting the uprights and adding 1/8" or so to the tops and bottoms of them. Now my skins will just hang over the top and bottom edges.

I haven't gotten my dome yet, but I figure that when the Rockler bearing ring is installed under the dome it will be flush with the bottom of it, but I might be wrong. I plan to do some adjusting when I get those. If I have to, I'll router out a channel in the top plate for the bearing to sit in so that the dome sits nice and close to the skin edge.

On the subject of routers: the practice among builders seems to be to use a router and a circle jig for cutting circles. I've got to say this sucks. It's noisy, creates shitloads of sawdust, it's hard to see what you're doing, and routers are hard to control. The bits overheat, the wood burns, and so on. The secret that all the Jedi know is to use a bandsaw. Take a little bit and set up a circle jig on the band saw. This can be just a scrap secured to the table, draw a straight line out perpendicular from the blade's leading edge, measure the radius of your circle, drill a little hole, insert a finish nail, put a little hole in the middle of your blank and you're ready to go. Cutting circles this way is accurate and almost effortless. In fact, if you're going serious about this job, spend some cash on a good band saw and you'll be a happy camper. Grizzly tools (grizzlytools.com) are cheap, reliable Internet power tools. My 220 volt Grizzly band saw will cut through a truck.

The problem is that you can cut the outer edge of rings like the ones in the plates for the frame, but you can't cut the inner circles unless you're willing to cut through the ring itself to get the blade inside. This can be worth it in some situations. You can go back, pry open the cut, smear wood glue in the gap, and let it dry and be good as new. But if not, then it's back the router and the circle jig. My ears are still ringing and I still have saw dust in my shoes. Use a good bit--maybe one that removes material for cutting instead of one for cutting grooves.

So after some back and forth, and some tweaking, my frame is done. I opted to drill pilot holes and counter sinks in all the intersections and put tiny screws in (1/2" and 3/4") to hold it all together. I am anticipating needing to disassemble it when I start trying to fit the various surface features on the R2. Once I am sure that I won't need to take the frame apart, I'll glue and screw it. It'll be bomber. It's bomber now just with screws.

2 comments:

Please, give me link to download XRumer 7.0!!!

Thanks!

Always yours,

miss MW

What skin templates did you use?

Post a Comment